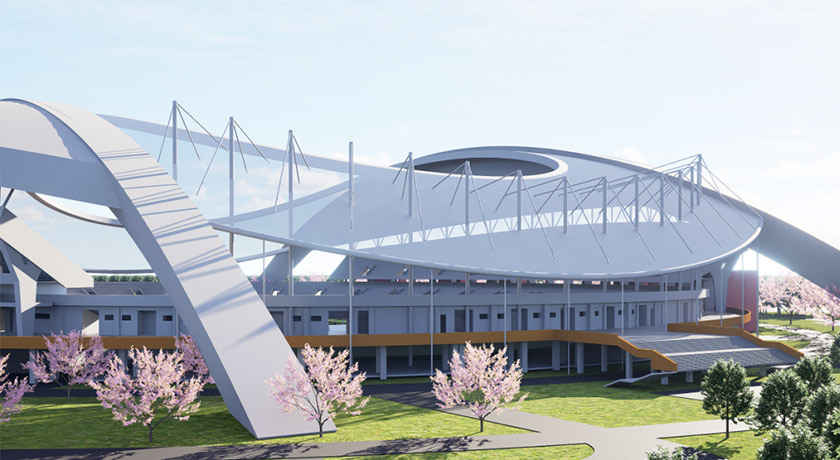

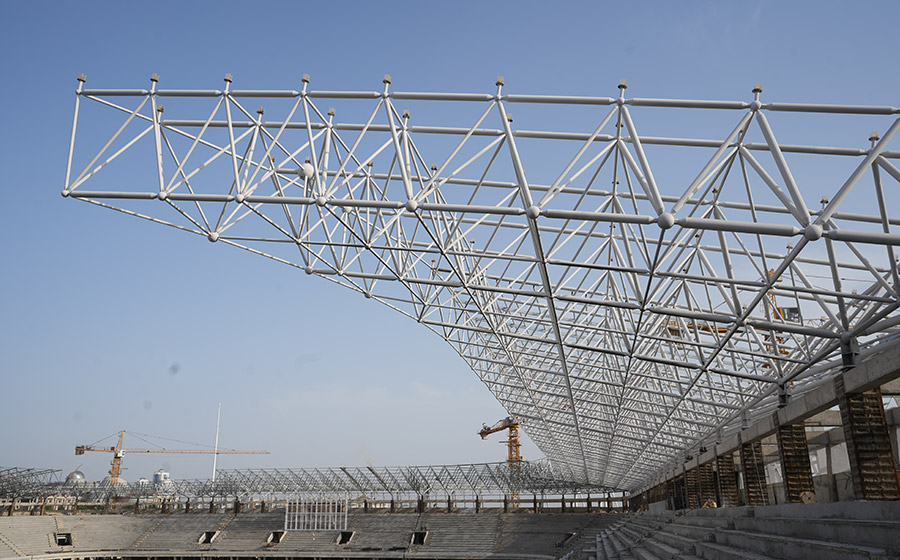

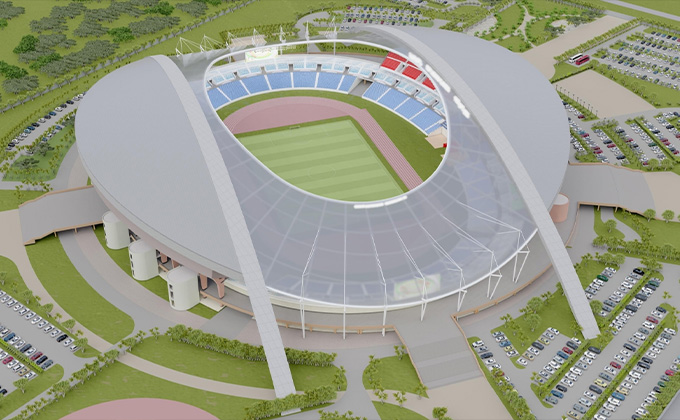

Steel Space Frame Tajikistan Stadium Roof

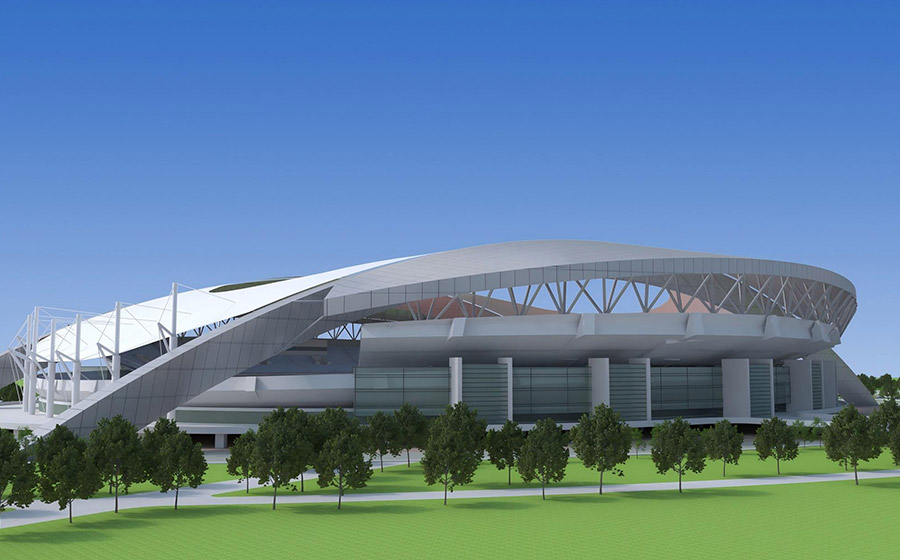

Deepening design and construction of a long-span steel space frame roof, integrating seismic performance with architectural expression.

VIEW PROJECT

Deepening design and construction of a long-span steel space frame roof, integrating seismic performance with architectural expression.

VIEW PROJECT

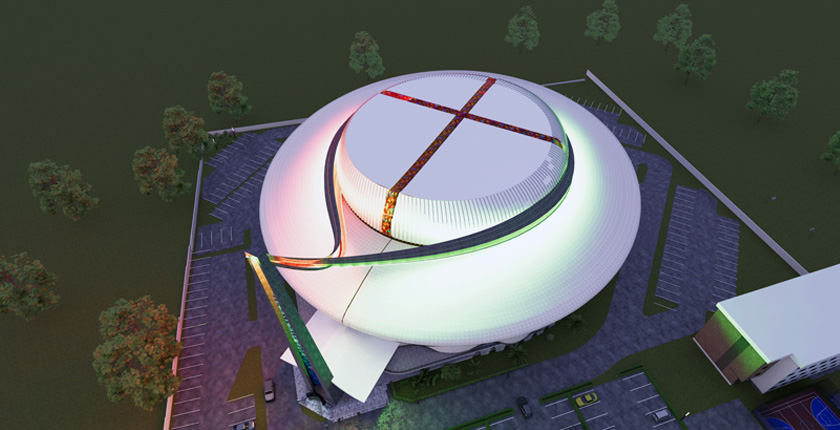

Integrated steel structure and ETFE membrane design, achieving 90% natural daylighting with low maintenance costs.

VIEW PROJECT

ETFE membrane roof design creating sacred light and shadow effects for religious architecture.

VIEW PROJECT

Large PTFE tensile membrane canopy ensuring all-weather operation in high passenger flow areas.

VIEW PROJECTPFM’s technical headquarters collaborates with top Chinese design institutes such as GDAD, offering strong technical support to ensure safe and efficient project delivery.

Our deepening design service ensures that all disciplines—including structure, MEP, façades, and special systems—are optimized for constructability, precision, and seamless integration with site execution.

We provide targeted design optimization proposals to improve functionality, cost-efficiency, and constructability—ensuring smarter, leaner, and more buildable solutions from the start.

All steel materials are sourced from Europian Union certified suppliersand complete mill certificates and third-party inspection reports provided.

Automated cutting, drilling, and welding ensure dimensional accuracy,Strict quality control to meet international and project-specific standards.

Factory-applied anti-corrosion coatings such as sandblasting + primer or hot-dip galvanization,Uniform coating thickness with strong adhesion and long-term durability

Multi-step inspections throughout production, covering welding, bolts, coatings, etc.,Full quality documentation with traceability.

Fabrication quality has passed technical review by the client’s engineering team;Proven reliability in similar high-standard projects.

Equipped with a self-built laboratory, the company maintains ISO-compliant production quality and has an annual capacity of 200,000㎡. Its products are exported to multiple countries and have been used in major projects such as the Qatar stadium and the Malacca resort in Malaysia.

Durable for 25–30 years, this membrane features excellent weather resistance, fire safety, and self-cleaning. With 10% light transmission and eco-friendly properties, it’s ideal for permanent, low-maintenance structures.

High-strength 316L stainless steel cables and CNC-machined connectors ensure precision and reliability. Each batch undergoes strict testing with traceable third-party reports. Pre-tensioned and equipped with standardized anchors, the system allows fast, accurate installation on complex joints.

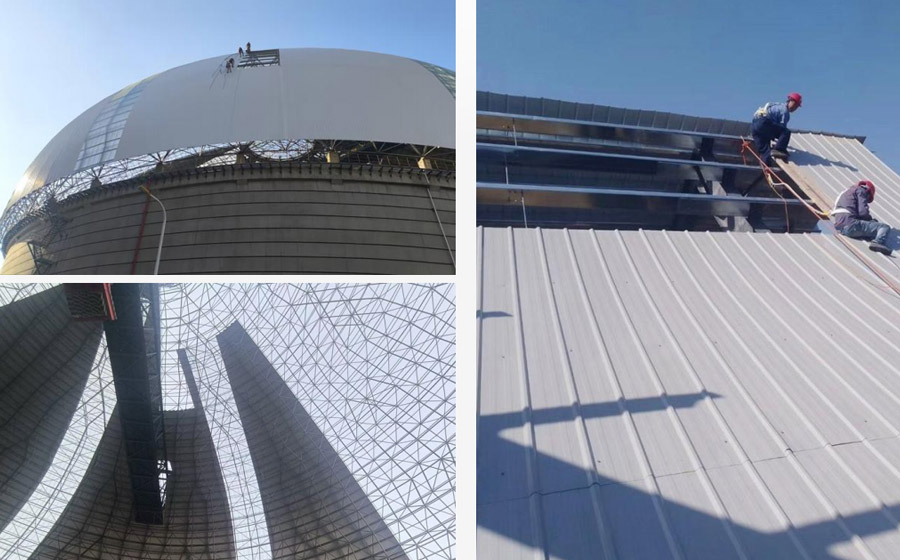

Integrating high-quality aluminum, precision forming, and anodizing or PVDF coating, this aluminum-magnesium-manganese alloy roof offers lightweight strength and excellent corrosion resistance against UV, acid rain, and salt spray, with a lifespan over 30 years. It is thermally stable, resists deformation, and suits large-span continuous roofing. The standing seam system ensures fast installation and reliable waterproofing, with strict quality control for efficient construction and low maintenance.

Selection of high-quality steel (e.g., Q235, Q355), with batch testing and certification to ensure strength compliance.

CNC plasma or laser cutting ensures precise rod lengths and end angles for accurate assembly.

Steel balls are drilled and threaded with high precision, along with pre-fabrication of high-strength bolts and custom connectors.

Hot-dip galvanizing or PVDF coating provides weather resistance, with optional fireproof coating for special project needs.

Partial mock-up of the structure simulates on-site installation to ensure dimensional accuracy and node alignment before delivery.

+86-18819472586